Duvall Slough Bridge #1136B (NE Woodinville Duvall Road) Re-Deck Project

Construction completed in summer 2024

The Duvall Slough bridge on NE Woodinville Duvall Road has a brand new deck and opened to traffic on August 27, 2024.

Status update

August 2025

NE Woodinville Duvall Road at the Duvall Slough Bridge reopened to traffic on August 27 after the re-decking project was completed. Thank you to the community for your patience and cooperation while we revitalized this east-west corridor.

Overview

The Duvall Slough Bridge is located on NE Woodinville Duvall Road, east of West Snoqualmie Valley Road. King County removed the top half-inch of worn-out concrete on the bridge deck and replaced it with one-and-a-half inches of new concrete. The project also rebuilt both bridge approaches and repaired two bridge expansion joints. This work protects and extends the life of the bridge for 30 years or longer.

The work required a six-week-long road construction closure on NE Woodinville Duvall Road between State Route 203 (Main Street/Carnation Duvall Road) and West Snoqualmie Valley Road. The road had to be closed because the bridge is too narrow to keep a lane open and maintain a safe work area. In addition, there could not be any vibration from traffic when crews repave the concrete or work on the expansion joints.

Why this project is needed

More than 10,000 vehicles cross the Duvall Slough Bridge on NE Woodinville Duvall Road every day. Crews have previously temporarily closed the bridge to repair potholes and patch up cracked concrete many times over the years. The concrete driving surface was too damaged to rely on short-term repairs. Overlaying the concrete bridge deck, rebuilding the bridge approaches and improving the bridge expansion joints are critical to keeping this vital east-west corridor open to traffic for years to come.

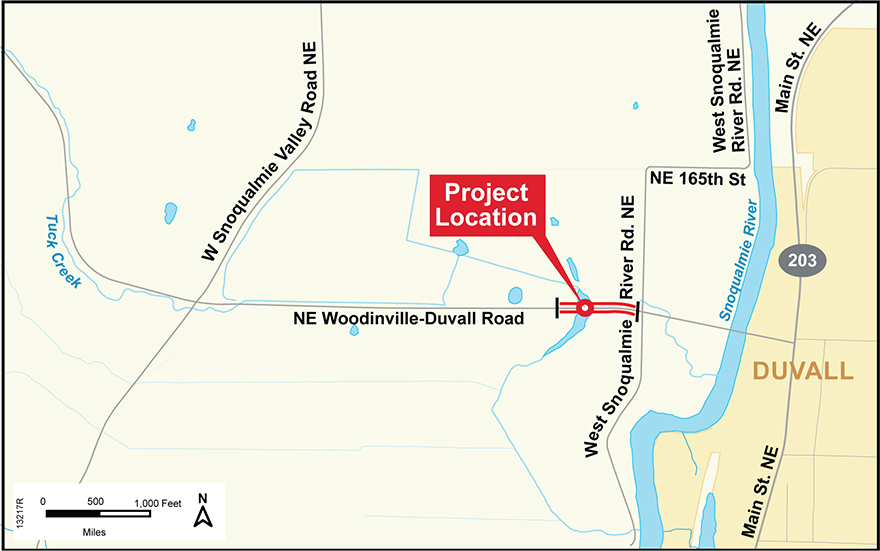

Project location

The project was located on NE Woodinville Duvall Road between West Snoqualmie Valley Road NE and West Snoqualmie River Road NE. Larger view (168KB)

Frequently asked questions

Photos

August 2024 – The new bridge deck is almost complete. The newly poured concrete has dried and is ready to bear weight.

August 2024 – Very specific conditions for air and ground temperature, and even wind speed, were required to ensure proper settlement of the concrete. Crews had to pour this overlay during the night to meet the specifications.

August 2024 – Geotextile wrap is used to stabilize the layers of compacted material.

August 2024 – Gravel material is compacted to support the new bridge approach. This project removes and rebuilds both bridge approaches.

August 2024 – Crewmembers rebuild the bridge approach area with rocks and gravel to improve the settlement issues at the approaches of the bridge.

August 2024 – Crews pressure wash the deck after removing the top layer of concrete with a hydro-demolisher. Cleaning the deck removes leftover debris to prepare the road for a new concrete surface.

July 2024 – A crewmember uses a large hose to vacuum the debris after hydrodemolition.

July 2024 – The bridge deck was demolished by a high-pressure water tool to selectively remove concrete. Hydrodemolition creates no dust pollution and the water used during the process is collected and treated on site to minimize risk of contamination.

Translate

Translate